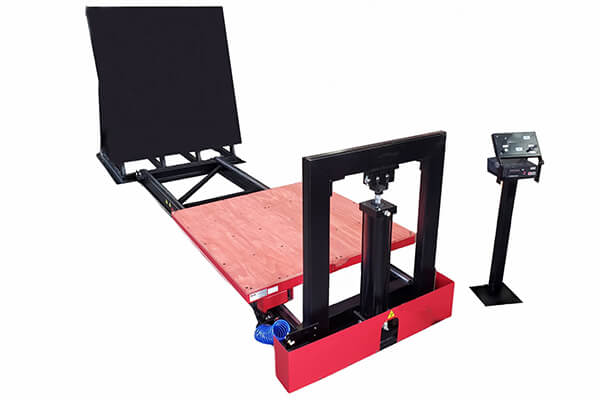

The incline impact test simulates the dynamic forces of the environment that packaged goods may experience throughout their shipping and handling operations. Simulate these dangerous dynamics with a shock test system.

The inclined impact test system uses a carriage to push the test sample down a slope at a predetermined speed and then hits a fixed backstop. The sample’s response to these extreme conditions demonstrates how your product will perform in a real-world supply chain environment, allowing design engineers to make improvements to the product and/or protective packaging as needed.

There are many laboratory applications for this side impact test, including product and packaging design, packaged product shipping simulation, and pallet unit load stability testing. If you want to learn about the Incline Impact Test, then our guide is for you. It covers everything you need to know about the incline impact test from definitions, steps, benefits, and more. In this guide, you’ll learn everything you need to know:

1. What is the inclined shock test?

In an oblique impact test, the shipping container, inner packaging, or both are evaluated to ensure that the contents are protected from impact. Furthermore, impact tests evaluate different designs of vessels carrying the same load and of the same size. We recognize the importance of oblique impact testing. Meeting oblique impact compliance requirements can be difficult. Linkotest incline impact tester understands the challenges and guides your companies through the process.

A horizontal impact tester or an inclined impact tester can be used for this test. Both tests use carriages that push the test sample along the track and into the backstop. Inclined impact testers use gravity to do this, while horizontal impact testers are powered by air or other suitable means.

The equipment used must comply with ASTM D880, ASTM D4003, or ISO 2244 standards. To perform either test, the product must be centered on the carriage of the impact slide in the correct orientation, with the front surface of the product in contact with the impact slide.

All your needs will be met under one roof by our expert engineers. When packages do not meet requirements, we assist you in finding solutions.

(Related Vibration Test Product: Vibration Test System)

2. Why is inclined impact testing important?

This compliance package test provides laboratory simulation of effects such as those found during handling and distribution cycles. Impact testing can also observe the gradual failure of the package and damage to the contents. Procedures in this test type may produce severe mechanical responses. As a result, packaging affects far more than product replacements, shipping claims, and customer satisfaction.

On the other hand, the benefits of testing packaging against shipping hazards may include:

- Balance distribution costs

- Confidence in product launch

- Improve customer satisfaction and expand market share

- Reduce time to market

3. Advantages of Inclined Shock Test System

Passing your packaged product through an inclined impact pre-shipment testing system before it is sent down the supply chain can provide valuable insight into its protective performance. Additional benefits gained from oblique impact testing include:

- Provides insights into optimal packaging design.

- Prevent product damage.

- Comply with industry regulations.

- Allows for repeatable testing.

- Minimize losses.

- Save costs and money.

- Improve the quality of deliverables.

For example, I have a friend who is a wine tube packaging manufacturer. He runs a series of reliability tests on the performance of his products before sending them to customers, including inclined shock tests. Because red wine is a fragile item, it is most important to test whether the wrapping paper tube can ensure the integrity of the wine during transportation. Through the inclined shock test, he can get the above benefits.

4. Incline Impact Testing Process

The incline impact testing process includes the following steps

- 1. Determine the appropriate test angle according to the shipping conditions of the package.

- 2. Place the package on top of the slope.

- 3. Release the package and let it slide down the ramp and hit the test surface.

- 4. Check the packaging for damage and evaluate its ability to withstand shocks.

Testing packaging materials for strength and durability is crucial to ensuring they can withstand shipping and handling stresses. By identifying potential weaknesses in packaging design and materials, improvements can be made to prevent product damage.

(Another Related Article: Environmental Test 101: A Full Guide)

5. How is the side impact test performed?

Typically, oblique impact testing is performed in a laboratory environment by design departments and test teams. The design department develops shipping packaging solutions, while the test team conducts impact tests and validates the design work.

However, there is no single procedure for performing tilt testing, as these methods depend on relevant industry packaging standards. Some of the major organizations developing guidelines for side impact testing include:

- American Society for Testing and Materials (ASTM).

- International Safe Transit Association (ISTA).

- Military Standard (MIL-STD).

- International Organization for Standardization (ISO).

Each test standard specifies the number of impacts required, the impact velocity, which side of the packaged product should be tested, and the order in which the impacts occur.

(Another Related Article: How do Mechanical Vibrations Occur?)

6. Inclined shock package test procedure

The oblique impact testing procedure begins with sample selection and conditioning. A specified number of samples is selected to accurately represent a portion of the fabricated unit. ASTM D4332: Conditioning of Containers, Packaging, or Packaging Components recommends conditioning testing. There are two procedures used for this type of testing.

Procedure A: Test the ability of the container to withstand shock.

Procedure B: Determine whether the container, shipping unit, or inner packaging can protect the contents.

1) Program A

First, the container is placed on a carrier whose face or edge will take impact beyond the impact end of the carrier. Depending on the purpose of the test, continue until failure. A failure is defined as the occurrence of a predetermined type of damage. This includes exposure or spillage of the contents or both.

2) Program B

This test method is performed similarly to Procedure A. However, this test method is continued until a predetermined number of impacts are applied at a specific impact velocity. Then open the unit and examine the contents. Finally, when the test is complete, a report is written with the following test information:

- Description of test samples

- Content description

- Determine the purpose of the test

- Conditioning method

- Test sequence

- Detailed test results

(Another Related Article: Vibration Test 101: A Full Guide)

7. Conclusion

Inclined impact testing is often used in conjunction with other packaging tests, such as vibration testing and compression testing, to provide a comprehensive evaluation of packaging performance for you. Overall, this detection method is an important tool in ensuring the safe and efficient transportation of your products, especially for fragile or sensitive items.

Leave A Comment