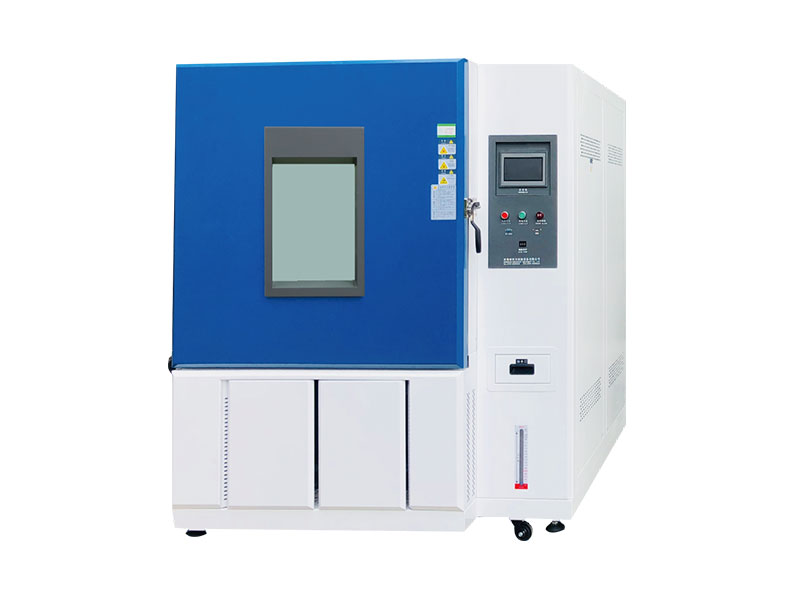

Linkotest Climatic Test Chamber

As an Environmental Chamber Manufacturer from China, Linkotest Climatic Test Chambers provide the flexibility to manipulate and control a wide range of environmental conditions. This includes temperature, humidity, pressure, vibration, and more. Besides, they are designed with advanced sensors, precise control systems, and uniform airflow distribution to ensure accurate and consistent environmental conditions.

These chambers are equipped with user-friendly interfaces and intuitive control systems, making it easy for operators to set up and control the desired environmental conditions during testing. Linkotest designs its chambers to comply with stringent industry standards and safety regulations. They incorporate features such as emergency shut-off mechanisms, temperature overload protection, and alarm systems to ensure the safety of both operators and test samples.

Linkotest understands that different test requirements may vary. That’s why their climatic chambers offer customization options to tailor the chamber’s size, performance specifications, and additional features according to specific testing needs.

Custom Climatic Chamber Solution

Linkotest Climatic Test Chambers offer reliable and efficient solutions for simulating various environmental conditions required for accurate and comprehensive testing across a wide range of industries.

Linkotest Environmental Test Chamber After-Sales Service

Warranty

We offer a comprehensive warranty on all our products. This warranty ensures that any manufacturing defects or malfunctions will be promptly addressed and resolved free of charge within the specified warranty period.

Technical Support

Our dedicated technical team is available to assist customers with any product-related issues. Whether it’s troubleshooting, installations, or general inquiries, our team is ready to provide prompt and efficient solutions.

Repair and Replacement

In the event that a product requires repair, we offer convenient repair services through authorized service centers. Our skilled technicians will diagnose and fix any issues, ensuring that the product performs optimally.

Spare Parts Availability

We maintain an inventory of commonly required spare parts to facilitate quick repairs. This helps minimize downtime, ensuring that our customers can continue using our products without significant interruptions.

Customer Feedback and Complaint Handling

We value our customers’ feedback and take complaints seriously. Our customer service team is committed to resolving any customer concerns promptly, ensuring their satisfaction with our products and services.

Product Upgrades and Enhancements

We continuously strive to improve the quality and features of our products. When applicable, we offer product upgrades or enhancements to provide our customers with the latest technology and improved functionality.

Training and Manuals

We provide comprehensive product training to our customers, ensuring that they fully understand the features and operation of our products. Additionally, we offer detailed instruction manuals and documentation to assist customers in using our products effectively.

Extended Support Contracts

For customers who require additional support beyond the standard warranty period, we offer extended support contracts. These contracts provide continued access to technical support, repairs, and other services, offering peace of mind and additional value.

Steps To Custom Environmental Test Chamber

Selection

Choose the types of environmental test chamber based on the necessary function, and then the right model based on the test specifications.

Quotation

Prepare a comprehensive quotation based on the customer’s requirements, including the cost, delivery details, and any additional services or customization requested.

Contract Execution

Engage in negotiation with the customer to finalize the terms of the order, including pricing, payment terms, and delivery schedule. Once all details are agreed upon, obtain the customer’s confirmation to proceed with the order.

Ensure that the equipment is manufactured to the highest quality standards. Conduct rigorous quality control checks and inspections at every stage of the production process to guarantee the system’s reliability and accuracy.

Coordinate with the customer to arrange the shipment. Provide regular updates on the shipping status, including tracking information, to keep the customer informed about the progress of their order.

Offer installation services and provide on-site training to the customer’s staff upon delivery. Ensure that the customer understands how to operate and maintain the system properly.

Environment Test Chamber FAQ Guide

As we all know, product quality is of Paramount importance in the manufacturing industry. Product defects can have huge economic consequences, such as lost sales and expensive product recalls. Moreover, there is an opportunity cost to your time spent correcting the situation. Please read on environment test chamber guide.

We integrate environmental testing into product development and manufacturing processes, which is a great way to avoid financial and reputational damage from premature failure.

At Linkotest, we help support our customers’ testing efforts to ensure products are safe and secure when they come to market. If you want to learn about environmental test chambers, then our guide is for you. It covers everything you need to know about environmental test chamber in terms of definition, how it works, classification, application, operating tips, and more. You’ll learn everything you need to know in this guide – let’s get started:

An environmental test chamber is a system that allows users to manipulate the environmental conditions of an enclosed space to conduct controlled tests on objects. In addition, it is also called a climate test chamber, stability test chamber, and environmental test equipment. Researchers, engineers, scientists, and manufacturers use these conditions to drive innovation and ensure that whatever they produce is safe.

According to the survey, your use of environmental testing helps to model the different climatic conditions and mechanical stresses to which the product may be exposed during its life cycle. And it also helps stimulate the lifecycle environment that the product encounters. The reliability and service life of your products can be verified by our environmental tests.

Environmental testing can help you understand if there are any weaknesses in the design or performance of your product, especially those that can occur at extreme levels. Yes, it also gives you the opportunity to determine the cause of the failure. In recent years, with the unification of national and international standards.

Environmental testing requirements are becoming increasingly mandatory in product categories in the Marine, aviation, transportation, military, and other industries.

Our environmental lab is a lab that creates artificial environments in a closed environment. And environmental test chambers can range in size from a half cubic-foot bench model all the way up to a 12,000 cubic-foot no-drop chamber.

Through the use of salt spray, the incubator can also reproduce various environmental conditions. For example warm and humid conditions, only temperature conditions, and corrosive conditions.

In essence, the stabilization chamber ensures that the products we use every day are fit for purpose. If you are developing and bringing a product to market, we recommend that it is in your best interest to ensure safety, quality, and customer satisfaction through rigorous testing. In some cases, it’s a legal requirement.

Linkotest designs and manufactures a wide range of environmental test chambers. It includes temperature humidity chamber, walk-in test chamber, thermal shock test chamber, fast change rate test chamber, agree chamber, xenon arc test chamber, uv test chamber, accelerated aging test chamber, rain & spray test chamber, salt spray test chamber, compound salt spray test chamber, laboratory oven, etc. These environmental test chambers can meet your different environmental test needs.

We’ve learned that companies in all industries, especially those manufacturing electronics, medical devices, automobiles, and anything that uses lithium-ion batteries, undergo rigorous environmental testing of their products and the components that make up those products.

What you need to know is that the main function of the environmental tester is to test the performance of the products we use every day in extreme climatic conditions. For example, a car that works well in a dry climate may not work well in high humidity. Environmental LABS allows manufacturers to stress test their products in a single environment.

On the other hand, environmental test machines can test products in continental climates with cold winters and hot summers, and in Mediterranean climates with higher temperatures. If the environmental test machine is properly calibrated to produce reliable results, it will be possible to simulate the performance of the product in its real cycle.

The most common applications are:

- Aerospace, Defense, and Telecommunications: Given the intended use of the finished product, these areas require “extreme” testing at temperatures, shock, and vibration well above or below freezing.

- Air Force, Defense, and Telecommunications: For the most part, these areas involve “extreme” testing at very high temperatures. At above or below zero degrees, shocks, bumps, and special vibrations are all taken into account for the finished product to be manufactured.

- Food and Beverage: Determine the shelf life of products, the shelf life of food products under optimal factory conditions, and the shelf life. It is also suitable for packaging and packaging/product contact.

- Chemicals/Cosmetics/Pharma: Another application where regulations are particularly stringent due to direct human health implications: see our in-depth analysis of the pharmaceutical industry and ICHstability testing

- Chemicals/Cosmetics/Pharmaceuticals: Another area that is particularly regulated due to its direct involvement in human health: see our in-depth analysis of the pharmaceutical sector and stability tests for the so-called intracerebral hemorrhage test

- Building Materials: The buildings we live in are subject to various types of constant stress, such as weathering. Building materials are greatly affected by these constant stresses. In this regard, see our insights into concrete carbonation and climate chamber material testing.

- Building Materials: The buildings we live in are constantly subject to various stresses, such as weathering. Building materials suffer greatly from these constant reminders. See our insights on material testing of carbonized concrete climate boxes.

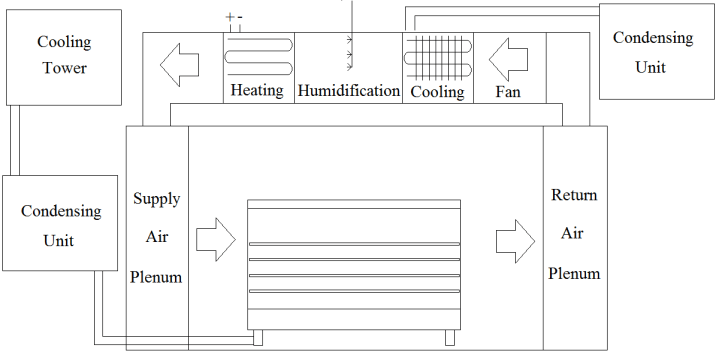

Depending on the purpose, our environmental laboratories have different systems to create and maintain environmental conditions. Next, we will briefly cover common air circulation, cooling, heating, humidity, and salt spray. However, it is important to research and understand the specifications of test equipment for a particular environment and to keep in close contact with the environmental chamber manufacturer.

In fact, air circulation is essential for environmental testing. Because laboratory and test room conditions are factors that give us accurate results. The Linkotest environment chamber features a combination of baffles and fans to optimize temperature and humidity conditions in the work area.

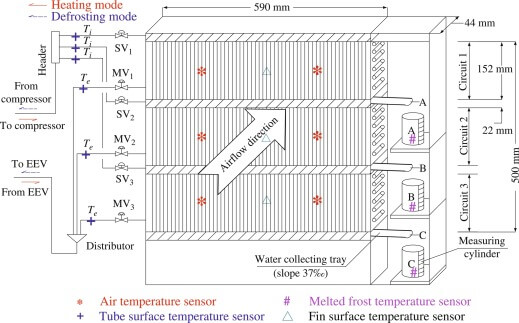

1) Cooling and Refrigeration

Usually, the stabilization chamber can quickly reach extremely low temperatures (-70 degrees Celsius). However, the cooling system on the Linkotest environmental test equipment has a different pull-down rate, averaging 2.5-10 degrees Celsius per minute. It is a compact sealing mechanical system because it is easy to maintain. When supplemented with booster cooling in the form of liquid carbon dioxide or liquid nitrogen, the temperature drops faster and lower, and rapid cooling may be required for stress testing.

Nowadays, modern test rooms are equipped with electric heating systems. The air passes through an independent, fast-responding NiCr heater with a ceramic core, providing us with accurate, controlled results. Standard models can reach temperatures above 120 degrees Celsius with an accuracy of +/- 0.5 degrees Celsius.

For heating and cooling, it is important to keep in mind the expected performance level of your room. While standard models can achieve high and low temperatures, they may not have a way to maintain extreme temperatures or rates of change without affecting small compressors. We recommend that you always consider the heat absorption rate of the product under test, as this can also affect the expected performance.

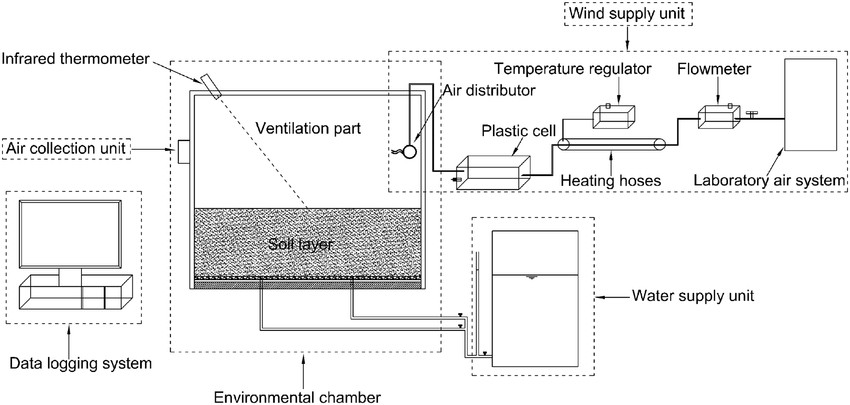

Our steam generators are custom-built and connected to environmental test equipment, which is designed to create humidity. Steam generators rely on a properly regulated water source to produce 20-95% relative humidity (RH). If you are equipped with special equipment, the humidity can be controlled at 10 ~ 98% RH.

To remove excess humidity, mechanical dehumidification systems are often used to speed up the pull-down process. According to the survey, some laboratories will strictly control the humidity, as the temperature rises or falls. Users who need to reach 5% RH humidity levels add desiccant air dryers to their test chambers.

2) How to create the salt spray

Here are the steps to create salt spray. First, the salt solution is prepared and stored in a container, and second, compressed air is used to force the salt solution and adjusted water through the nozzle to form a fine fog in the laboratory. Linkotest Salt Spray Chamber is a unique style of salt spray chamber. Because transparent walls allow overall visibility of the product during testing.

The environmental chamber works on the principle that all conditions can be managed manually by various mechanical processes.

Did you know that temperature control is heated by an electric heater or cooled by a cooling device cooling the box? For example, to simulate the corrosive effects of seawater, the researchers sprayed a salt solution through a nozzle inside the room, which created a fine mist covering the entire product. Therefore, humidity in the laboratory can be simulated in two different ways. The first is to use a heat source to evaporate water, and the second is to use ultrasonic technology.

However, the design of environmental laboratories can be very complex or very simple. It depends on the type of tests they perform. They are available in a variety of sizes to suit the manufacturer and the required test conditions. Examples include benches for testing small items and room sizes for cars.

While the size and type of environment are factors, you don’t need to worry. Because modern environmental test machines have technical controls, they can provide instant data and readings. This gives technicians the opportunity to adjust and change conditions during the process.

As shown in the figure below, in a stable environment test device, we program a specific set of variables into the chamber and keep them constant over a long period of time.

Usually, a stabilization chamber is specifically designed to maintain a constant and accurate temperature as part of an age test. They have plumbing and electrical control systems that sustain the environment over a long period of time.

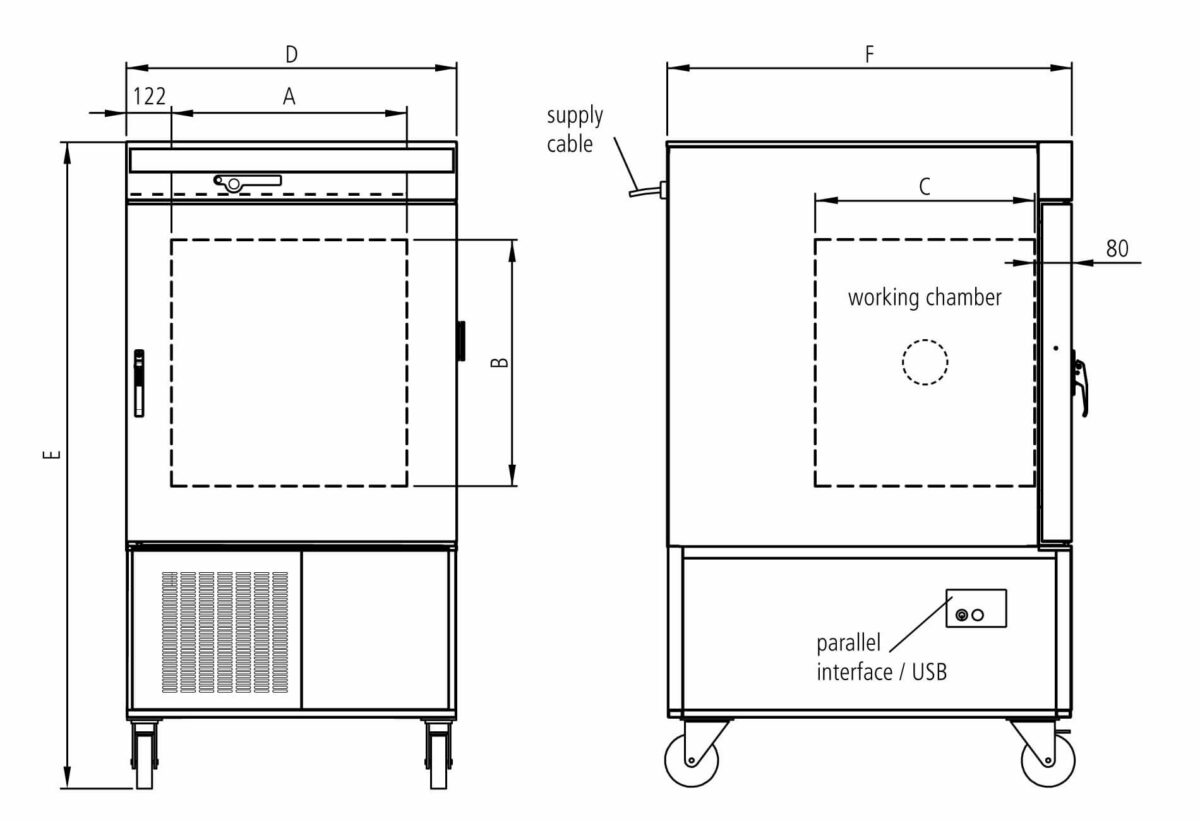

1) Test chamber design factors

In fact, the size of the environment chamber depends on the type of product being tested. Sizes range from 1 cubic foot to 12,000 cubic feet and can fit a single aircraft. Here are pictures of two types of environmental test equipment. The first is a small ISO environmental tester for industrial hot air drying tests. The second is to operate under different temperature and humidity conditions. It’s 8’x4’x4 ‘. In addition, there is a wind-driven rain machine whose wind turbines can produce 160 MPH wind speeds.

Our technicians can monitor the tests from their desktop or laptop computers. The set point, temperature, and humidity views can be used at any time using pre-built graphics or customized to customer-specific conditions. The new technology allows users to monitor and adjust test conditions during testing, unlike the old model room that provided data at the end of the test. As you can see from the controller display, it monitors data and graphs of air temperature, product temperature, and humidity, and sends data every second.

2) Automated labs

What you need to understand is that automated LABS can be programmed in a variety of ways that can continuously produce a variety of environmental conditions. Such a series of steps can be programmed into the cabin. These include ramps, descends, jumps, and automatic stop and start. At this point, the purpose of the automation room is to test the durability and life of the product. Its system relies on a robust programmable logic controller (PLC) designed to be used in industrial environments.

The light stability test creates the entire range of exposure levels that the product may experience during use. Because the test chamber can accurately analyze the influence of sunlight, ultraviolet light, and various colors of light. And the light can cause the color to fade or the product to deteriorate. The collected data provide visual color evaluation, color change comparison, isochromatic detection, and color matching for different spectral power distributions.

What we must tell you is that for critical healthcare products such as pharmaceuticals and pharmaceuticals, the forced degradation caused by the light stabilization chamber exceeds the extreme conditions of the normal environment. Since 1990, light stability testing has become very common in the pharmaceutical, coatings, ink, and dye manufacturing industries.

According to the investigation, the International Coordinating Committee on Technical Requirements for Medicinal Products for Human Use (ICH) has specific light stability testing criteria in Q1B, and they allow the use of two light sources for drug testing. Finally, the Q1B test showed no unacceptable changes in the light source.

Usually, temperature testing is the most common type of product stress testing because temperature fluctuations can cause a product to expand or contract. The rate of temperature change is determined by the type of product being tested. The temperature range is -80°C to +250°C (-112°F to 482°F).

What you should know is that humidity testing is the second most common environmental stressor that affects the inner workings of a product. Moisture or leakage can lead to oxidation and corrosion.

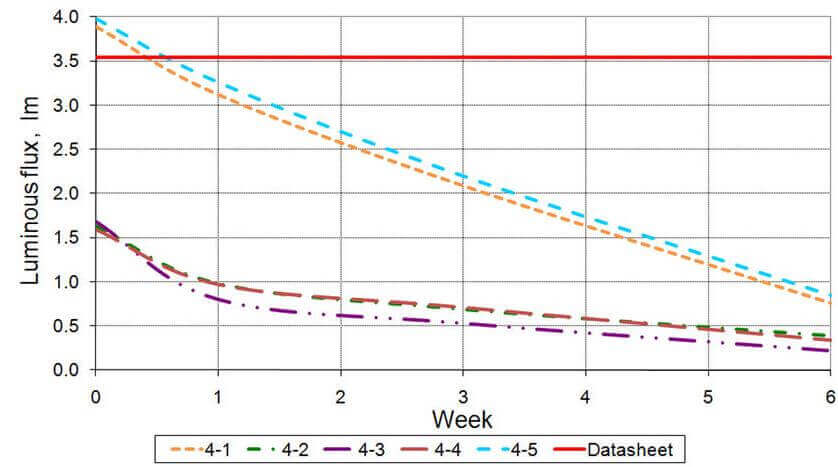

We recommend that you use a set of atmospheric conditions to accelerate the aging process to determine the life of the product. It is mainly used for new products that have not gone through the normal aging process. Vibration and shock caused by temperature and humidity are tested using the full spectrum. The following figure shows the aging process of LED light flux attenuation.

1) Comprehensive tests

Our comprehensive tests combine temperature and humidity tests with vibration tests. Because they produce rapid temperature changes at different humidity levels. Vibration testing measures the response of your product when it is transported or moved.

In situations where rapid temperature changes are more severe than the expected range, the product may experience. Our tests to verify the reliability of our products are used to determine the cracking and strength of adhesive materials.

Altitude tests the suitability and reliability of the sample under low pressure, high temperature, and altitude conditions while measuring electrical performance parameters. In addition, temperature and altitude environmental test equipment is used for vehicles, computers, and electronic components in alpine conditions, as well as for air cargo packaging.

Humidity tests simulate soaking and heavy rain conditions. We use a water chamber for water mist testing with a separate recirculation system. In this way, water is injected through a nozzle with a flowmeter to regulate the water supply.

2) Electric Vibration Test

Electric vibration testing or driver systems can be used in a variety of areas. For example, it is used in PCB circuit boards, mobile phone chips, aerospace equipment, military aircraft, auto parts, tanks, and heavy weapons. There are also electric vibration tests or driver systems for shock, vibration, and stress screening failure analysis of equipment.

3) Electromagnetic radiation test

In fact, the electromagnetic radiation test is to test the electromagnetic wave stream emitted by the product. This is required by several countries and must be repeated on production models.

You can see that cyclic corrosion testing accelerates the corrosion process under laboratory conditions, which is widely used in the automotive industry. Its material can be soaked, dried or sprayed. But the testing process is complex, involving multiple exposure processes.

According to the survey, the salt spray test is another accelerated corrosion test that exposes the sample to salt spray or salt spray. The tester applies continuous, indirect fog or sprays to the sample.

As we all know, the climate test is a test carried out under various weather conditions. To determine the reliability and longevity of the product. Climate testing includes many other forms of testing, such as temperature, humidity, corrosion, and sand.

A dust test is a form of test in which dust and other possible contaminants circulate at high speed in the laboratory. Particle counts and velocities are adjusted to predetermined specifications for the material being tested.

Finally, vacuum tests are mainly tests of equipment used in outer space or processes such as vacuum drying and coating.

#1. Cytogenetic analysis and stability test

Cytogenetic analysis is designed for sliding drying analysis of in situ and non-in situ cell samples. For you to get the best results, the controlled temperature and humidity must be the same as the environmental conditions for chromosome reproduction. It is worth noting that the results of chromosome analysis are highly dependent on the conditions under which methyl acetate or ethyl acetate fixative evaporates.

A stability test is a test whose purpose is to provide evidence of how the quality of a drug product changes over time under the influence of various environmental and atmospheric factors. The most common factors are temperature, humidity, and light. The test results outline storage conditions, retest times, and shelf life recommendations. We investigated the U.S. Federal Drug Administration (FDA) Q1A(R2) entitled “Stability Testing of New Drug APIs and Formulations” outlining testing guidelines.

Finally, in addition to the light stability test, there are other drug stability tests. Examples include acceleration, intermediate, freeze-thaw, bulk, and post-opening time (PAO). Another FDA requirement is to determine the expiration date, which must be supported by real-time (RT) stability testing.

Usually, with proper maintenance, an environmental chamber can continue to operate for 10 years or more.

In order to extend the service life of the environmental test chamber, you should carefully clean and inspect the test chamber regularly. In fact, the true cost of capital equipment cannot be measured by its purchase price alone. You must also consider the costs involved in maintenance and repair, labor costs for parts, and costs associated with downtime in the climate chamber.

Here are some common cabin maintenance scenarios:

- Verify operation

- Complete Refrigeration System Inspection

- Check the humidity system (if any)

- Complete electrical system inspection

- Check for leaks

- Check all gaskets and seals

- Complete cosmetic inspection

- clean filter

- Repair parts that need repair

- final system test

All climatic test chamber maintenance is done by certified technicians.

Remember that the easiest way to manage your test environment is through automation. By automating build and deployment, you can successfully manage your environment.

Continuous integration (CI) tools, such as Jenkins, a free and open-source automation server written in Java, are among the most popular CI tools used for this purpose in the software industry. This tool not only helps you automate the deployment process but also helps run test suites.

Another way to manage your test environment is to use detailed documentation that describes it. For example, how to create an exact copy of your production environment. However, this more manual approach is prone to human error.

When purchasing a new environmental test chamber, most labs focus on purchasing factors such as functionality, performance, and cost-effectiveness. But they rarely take into account the installation requirements and thus cannot ensure a successful installation process.

We know that setting up environmental testing equipment is not easy. A number of obstacles may arise during the installation process. For example, the worst-case scenario is that the chassis is damaged or incorrectly installed. To help you shorten installation time and avoid these potentially expensive hurdles, we have prepared a 5-step guide for installing a new environment test box.

1) Choose the correct installation location

Environmental testing equipment should be installed on a flat floor that can withstand the weight of the room, but your room should also be spacious enough to ensure optimal functionality and proper maintenance. In addition, the room must be protected by atmospheric media.

2) Consider the outside temperature

Another thing you must consider when choosing the right location to install your new environmental test chamber is room temperature. When setting the temperature, be sure not to forget the heat emitted by the box during the test.

You can install an air conditioning system if necessary to ensure the normal running of the equipment room.

3) Focus on electrical systems

According to the performance level of the equipment room, you need to ensure that the power supply system of the equipment room is properly configured. This environmental test device may require specific plugs and cables, so please check its specifications carefully.

You may encounter high current lines, so equip your lab ahead of time.

4) Make sure the water is connected

There are two water connections to consider – the water connection for the humidification system and the water connection for the water condenser. This is especially true if your environment test equipment is condensed but doesn’t have a built-in water softener.

In this case, you will need an external desalinated water supply system and an additional water condenser connection, which must provide water with special characteristics that meet the technical requirements of your environmental chamber model.

5) Take precautions to prevent clogging

If your room has a recirculation system for dehumidified water, you will also need a drainage system near the room. This is an important measure to prevent drainage blockage when the specimen is dirty. Alternatively, water can be collected by letting it flow into a container. Install environmental chambers according to NEMA standards

The National Electrical Manufacturers Association (NEMA) sets standards for all environmental compartment installations, so make sure your installation meets not only the specifications of your cabin but the standards established by NEMA.

Otherwise, an unsuitable environmental test chamber installation could incur additional costs to your lab, not to mention jeopardize the quality of your test results.

Environmental testing standards establish criteria for the ability of a product, material, or component to withstand different environmental conditions over a period of time or expected life.

Standards vary by industry, type of test program, and intended use. Examples of environmental or climatic conditions suitable for standard test parameters include:

- very high and very low temperatures

- rapid temperature changes

- humidity change

- salt spray and salt spray

- vibration

- High and low pressure

Environmental testing standards apply to a wide variety of industry sectors, and some standards apply to multiple industries.

1)List of examples

Here are some canonical examples in alphabetical order:

#1. AECTP 100

The North Atlantic Treaty Organization (NATO) provides guidance in Allied Environmental Conditions and Testing Publication (AECTP) 100, Environmental Guidelines for Defense Materials. Test criteria include changes in temperature, humidity, and salt.

#2. ASTM

American Society for Testing and Materials develops standards for a variety of industries, including aerospace, automotive, construction, chemical, consumer products, food processing, medical devices, IT, telecommunications, manufacturing, pulp and paper, and safety and security.

#3. FDA

The U.S. Food and Drug Administration is responsible for promoting and protecting public health. FDA standards ensure that products meet specific requirements for identity, strength, quality, and purity under the influence of various environmental factors.

#4. IEC

The International Electrotechnical Commission (IEC) is the world’s leading organization for the preparation and publication of international standards for all electrical, electronic, and related technologies.

#5. IEEE

The Institute of Electrical and Electronics Engineers (IEEE) is the world’s largest professional society dedicated to advancing technological innovation and excellence.

#6. ISO

The International Standards Organization is an independent, non-governmental membership organization, the world’s largest voluntary international standards development organization, best known for its ISO 9000 quality management standards.

#7. JEDEC No. 22-A104D

Joint Electronic Device Engineering Council implements a global standard for the microelectronics industry, providing temperature cycling solutions for component and solder interconnect testing. It specifies the temperature range.

#8. MIL-STD

The U.S. Department of Defense Military Standard, also known as MIL-SPEC or MilSpecs, is a defense standard issued by the U.S. Department of Defense to support the goal of standardization.

#9. RTCA

Technical guidance developed by the Radio Technical Commission for Aeronautics for use by government regulators and industry.

#10. SAE

The Society of Automotive Engineers International is the professional association and standards organization for engineering professionals in the transportation industry, such as automotive, aerospace, and commercial vehicles.

#11. SR-332 (Telcordia)

These standards contain recommended methods for predicting the hardware reliability of equipment and units, especially electronic equipment. They include test methods over a range of operating temperatures to predict failure rates.

#12. UL

US-based global safety consulting and certification agency that provides safety-related certification, verification, testing, inspection, auditing, consulting, and training services.

#13. UN/DOT 38.3

Authorized by the U.S. Department of Transportation, United Nations Manual of Tests and Criteria for Lithium Batteries, 4th Edition.