Linkotest Drop Test Machine

A drop test machine is used to test the damage caused by dropping the product package and to evaluate the impact strength during transportation and handling.

Our drop testers are used for the purpose of dropping tests while keeping the attitude of the specimen and investigating its effect. In addition, it can be used not only for electricity and electronics but also for drop tests in various fields such as medicine, food, and pharmaceutical.

Linkotest has proudly served the drop test industry with mechanical drop testers for mobile products, rotating drum testers, drop testers for packages, and all types of drop testers for large items for over 23 years.

Linkotest Drop Tester Features

Linkotest drop test machines can perform safe drop tests on a wide range of products from mobile devices and components to packaged goods.

Linkotest Drop Test Machine After-Sales Service

Warranty

We offer a comprehensive warranty on all our products. This warranty ensures that any manufacturing defects or malfunctions will be promptly addressed and resolved free of charge within the specified warranty period.

Technical Support

Our dedicated technical team is available to assist customers with any product-related issues. Whether it’s troubleshooting, installations, or general inquiries, our team is ready to provide prompt and efficient solutions.

Repair and Replacement

In the event that a product requires repair, we offer convenient repair services through authorized service centers. Our skilled technicians will diagnose and fix any issues, ensuring that the product performs optimally.

Spare Parts Availability

We maintain an inventory of commonly required spare parts to facilitate quick repairs. This helps minimize downtime, ensuring that our customers can continue using our products without significant interruptions.

Customer Feedback and Complaint Handling

We value our customers’ feedback and take complaints seriously. Our customer service team is committed to resolving any customer concerns promptly, ensuring their satisfaction with our products and services.

Product Upgrades and Enhancements

We continuously strive to improve the quality and features of our products. When applicable, we offer product upgrades or enhancements to provide our customers with the latest technology and improved functionality.

Training and Manuals

We provide comprehensive product training to our customers, ensuring that they fully understand the features and operation of our products. Additionally, we offer detailed instruction manuals and documentation to assist customers in using our products effectively.

Extended Support Contracts

For customers who require additional support beyond the standard warranty period, we offer extended support contracts. These contracts provide continued access to technical support, repairs, and other services, offering peace of mind and additional value.

Steps To Custom Drop Test Machine

Selection

Choose the types of drop test machine based on the necessary function, and then the right model based on the test specifications.

Quotation

Prepare a comprehensive quotation based on the customer’s requirements, including the cost, delivery details, and any additional services or customization requested.

Contract Execution

Engage in negotiation with the customer to finalize the terms of the order, including pricing, payment terms, and delivery schedule. Once all details are agreed upon, obtain the customer’s confirmation to proceed with the order.

Ensure that the equipment is manufactured to the highest quality standards. Conduct rigorous quality control checks and inspections at every stage of the production process to guarantee the system’s reliability and accuracy.

Coordinate with the customer to arrange the shipment. Provide regular updates on the shipping status, including tracking information, to keep the customer informed about the progress of their order.

Offer installation services and provide on-site training to the customer’s staff upon delivery. Ensure that the customer understands how to operate and maintain the system properly.

Drop Test Machine FAQ Guide

The strength of the product is determined by the height of the landing point and the impact time. The best way to test is to have an objective third party do it so you can compare the results to other manufacturers in the same industry. With the help of the Linkotest drop test machine, you can easily test the drop strength of these test instruments.

If you want to learn more about drop testing machines, then our guide is for you. It covers everything you need to know about drop testing machines from definitions, working principles, applications, operating techniques, and more. You’ll learn everything you need to know in this guide. — Let’s get started:

Drop testing machines are used for evaluating the impact strength and damage caused by falling products during transportation and handling. For example, the surfaces, edges, and corners of the packaging are free to fall.

Drop testing machines can be tested according to GB, ISO, ASTM, BS, DIN, JIS, and other national or international standards. In addition, it is the ideal testing and research equipment for factories, technical supervision departments, commercial inspection agencies, scientific research institutes, universities, and colleges.

Drop testers simulate drop and rotary shocks that can affect packaging during transportation and handling. Therefore, the machine (also known as the “free fall tester” and “vertical impact tester”) uses the latest technology to simulate landing points on planes, edges, and corners.

Linkotest designs and manufactures drop test machine including but not limited to the following products:

- drop tester for mobile products

- package drop tester

- drop tester for large objects

- drum tester

These products can meet your different drop test needs.

During the distribution cycle, our products are threatened by conditions such as drops or impacts that may endanger their safety. During transportation and handling, damage to goods from drops is common, including corrugated cardboard wrinkles, perforations, or other marks such as tears and breaks. It is estimated that 11 % of shipments to distribution centers are damaged by accidental drops.

To predict and prevent the consequences of this problem, drop tests simulate drop and spin collisions that can affect packaging and products during handling and distribution. In the end, we conclude that packaging is their only protection against these dangers.

Drop testers work by simulating drops and impacts and showing how they affect load and packaging. In this way, it can help prevent problems during the transportation and handling of goods. Drop testers are very useful for companies whose success depends on the safety of their goods during transportation.

The main purpose of drop test equipment is to obtain data that allows you to optimize the packaging of your shipped goods. Using a drop test machine can give you insight into how your product performs during and after distribution. You collect this information through controlled testing to make more informed decisions about the design of your products and packaging.

The packages that you optimize by implementing package testing will have the following benefits:

- It protects the product during transportation and allows you to choose the right packaging to keep your cargo safe. Companies that need to protect their products and ensure that they arrive at their destination in perfect condition, thus guaranteeing end customer satisfaction, seek drop testers. In addition, drop testers allow shippers to assess the ability of packaging systems to protect their products during transportation.

- Drop tests provide you with useful information to reduce potential shipping risks. In this regard, drop testing machines are particularly necessary to simulate the transport of dangerous goods or particularly fragile packages in the pharmaceutical sector. In addition, you simulate a collision through free fall or rotation. You can protect these loads by predicting unexpected events that may affect them.

- Drop testing machines help save costs. If you are using a drop tester in the laboratory, you can design protective packaging for shipping goods.

- A drop test before shipping can prevent your products from being over-packaged, reducing unnecessary costs for your company. This test also prevents inadequate packaging, which can put your goods at risk. And it means higher costs due to product shrinkage or damage during transportation.

1) Other aspects

In addition, the drop test machine is important in other ways as well:

- It is the basic tool for most packaging tests established according to international standards. For example, simulations using a drop testing machine are part of Amazon’s ISTA program.

- Drop testing equipment also allows you to perform simulations that comply with good shipping rules in effect.

- There are many benefits to providing drop testers for in-house LABS. Among other things, it can be tested independently. Allow your company to conduct comprehensive, rigorous testing at your convenience, without relying on third parties.

- Allows drop tester manufacturers to evaluate the type of packaging needed for safe shipping and Reduces the risk of product damage and the associated costs. Otherwise, assesses whether a product or packaging system meets the needs of governments, businesses, and companies.

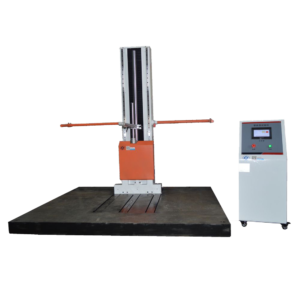

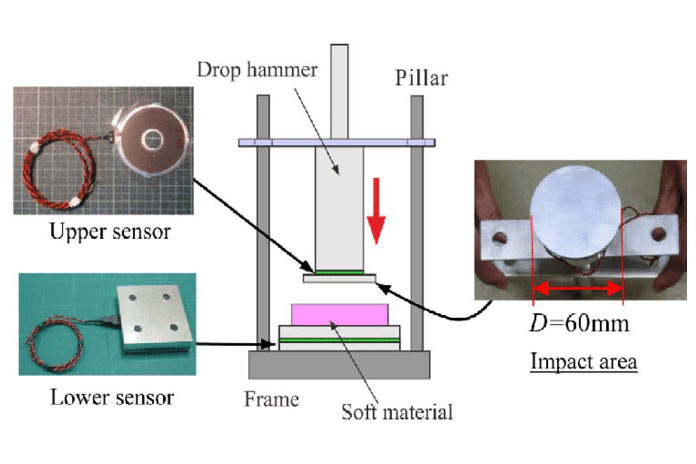

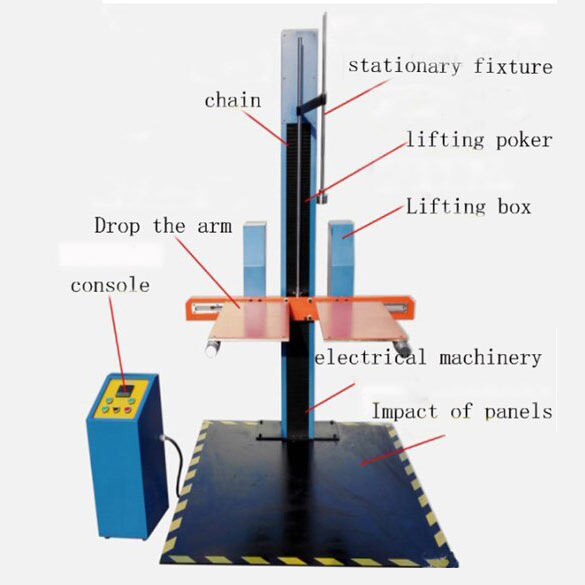

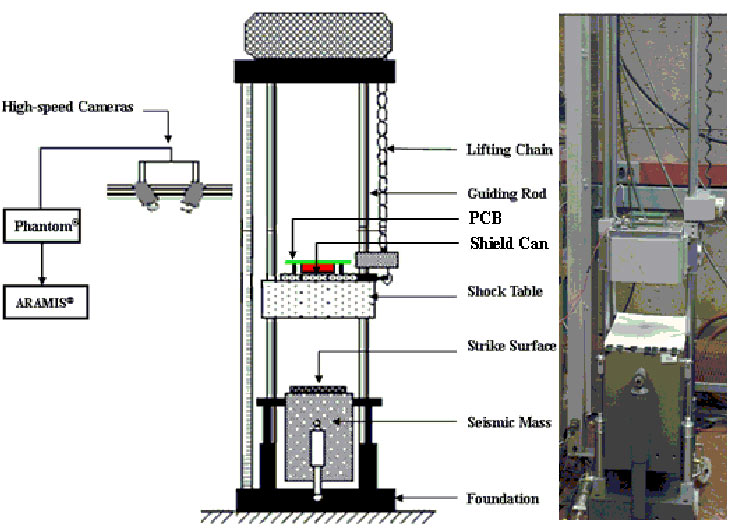

The structure of the drop testing machine we described above includes an impact base plate and an electric control box. The impact bottom plate is provided with a steel riser, the vertical frame is provided with a wire rod, the outer side of the screw is provided with a lifting seat, and the lifting seat is penetrated.

A connecting rod is arranged on the lifting seat, and a fixing plate is arranged on the connecting rod. The fixing plate is provided with a lifting rod, and the lower side of the lifting rod is provided with an E-shaped support frame that can be moved up and down. A U-shaped fender bar is also provided on the vertical frame, and a display is provided on the electric control box.

When you use the zero drop testing machine, through the control of the electronic control box, the package is fixed between the lifting rod and the support frame to fall onto the impact base plate. For the edge plane impact test, you can adjust the height of the lifting rod according to actual needs to obtain the test parameters in different situations.

During the test, the probability of the package part slipping is low, and the zero drop tester is particularly suitable for the drop test of cubic packages than traditional ones. Because it is cleaner, more environmentally friendly, and more space-saving than the traditional hydraulic lifting structure.

In fact, impact drop testing can benefit a wide range of products. Some of the products that can be drop-tested using this method include:

- Electronic products (e.g., smartphones, personal computers, tablets)

- Laboratory equipment

- Medical devices

- Pharmaceuticals

- Bulk food packaging

In general, if you are transporting delicate or high-value goods that are not suitable for rough handling, or your product is not in perfect shape. You are likely to be rejected by consumers. In this case, a drop test is a good idea. However, network racks and window trays have very different design characteristics. But drop tests on both systems will provide valuable information to Oems. While the drop test is particularly useful in these situations, it can also be used for lightweight products.

Drop tester machines can simulate transportation and distribution environments in a way that exposes the various impacts that packaging can endure as it moves through the supply chain. By controlling the height at which the test sample falls, you can control the speed of the impact, which is proportional to the impact energy.

Verifying the effectiveness of your product packaging through drop testing ensures that your products remain safe and intact during transport. When your products can withstand harsh selling conditions, you can save money, reduce losses, and ensure customer satisfaction.

More specifically, a drop test is a test designed to check the structural integrity of a product. Drop testing typically involves an object falling from a predefined height onto another object or surface. The object being tested can be either the object being removed or the object/surface on which the object being removed is located.

If the object being tested is a dropped object, its ability to withstand a specific physical impact is measured by throwing it from a given height onto a standardized hard surface. If the surface being dropped is the object being tested, then its ability to withstand a specific impact is measured by dropping a standardized weight and mass from a given height. Finally, the former type of test is typically used to ensure the safety of portable hazardous materials, while the latter type of test is used to ensure the effectiveness of fall protection systems and to identify any surfaces that may present a fall hazard.

1) Fall tests in occupational safety

In occupational safety, fall tests are most often used to demonstrate the effectiveness of fall protection products. This is done by product manufacturers and employers who install products in the workplace. The judicial standard is met by demonstrating that the safety net can withstand the weight of a sandbag or other standardized object dropped from a specific height. In fact, the fall test was designed to simulate the impact of a person falling onto a web.

During the safety cable test, we tie a certain weight of sandbags to the safety cable and release them from the height in a certain way. To show that the cable can support a falling worker. Guardrail structures also frequently use drop tests to verify the ability of the top rail to support the load required by the 200-pound OSHA drop protection standard.

For certain work surfaces that may be fragile, such as skylights and other glass barriers. This can be tested by throwing a sandbag directly on it to confirm that it won’t break if a worker accidentally drops it.

What you should be aware of is that these tests, as well as drop tests to ensure the safety of hazardous material testing, are usually conducted under laboratory conditions by accredited testing organizations. In this way, a recognized product quality certification can be provided.

In the workplace, employers are obliged to conduct fall tests. In this way, it is confirmed that they have successfully installed recognized fall safety equipment. For example, OSHA requires testing of safety net devices. The method is to drop a 400-pound sandbag, 28 to 32 inches in diameter, from the highest surface where employees are exposed to fall hazards.

The working principle of a drop tester is:

- The falling point, angle, edge, and surface are freely selected, with the center of gravity support, so that the falling point is accurate.

- The machine adopts a large diameter single-axis structure, coordinating spiral lift, and accurate and fast positioning.

- Multiple machines are equipped with up and down upgrade limits to protect the machine from exceeding the safety limit.

- The jig can be used to place large objects to be measured.

- Quickly swing the palm blade away from the object to be measured, so that the object to be measured falls naturally.

- Technical drop points can be freely selected 1 corner, 3 sides, or 6 sides, with the center of gravity fixed device, the drop point is accurate.

What you need to know is that drop tests create conditions for free fall and sudden impact at different heights and angles. The device repeats this process until a packaging fault is exposed. Drop test programs typically focus on specified:

- Drop height: Different test standards specify a range of drop heights, which may depend on the size, weight, and simulated shipping environment of the test item.

- Test item orientation: When testing goods in different directions, the area affecting the product can be better evaluated.

- The number of drops: Typically, a package will be dropped multiple times in different directions, all based on the intent of the reference test standard.

In addition, the procedure for performing a vertical drop test will vary from model to model, depending on whether the load is large or small. In the case of large loads, the cargo is placed on a lifting platform driven by a pneumatic mechanism. As the platform descends, it is wedged into the base, allowing the load to hit the impact surface.

On the other hand, smaller loads require load tests on the beam. The beam rises and contracts, causing the load to fall. In addition, the model of small cargo allows for the placement of obstacles to counteract the impact of the load.

In both cases, the drop tester may include an arm mechanism that allows edges and corners to drop. And extend the capabilities of the machine to give you results that are closer to real life.

The drop criteria tell you how many times the sample needs to drop, and in what order it needs to happen. And the different types of drops that need to be simulated. For example, vertical, rotation, and corner drops. Drop tests Two types of tests can be performed, including drop tests and rotary drop tests.

ASTM and ISTA tests are the two most common drop test standards. They provide different guidelines for drop height relative to weight. In addition, the type of testing can vary depending on the project and the desired results. Because some products, materials, and equipment require multiple tests to get the best results.

Drop testers range in price from a few thousand dollars to tens of thousands of dollars, depending on their size and functionality. If you want to know the detailed price of the drop testing machine, you can contact the drop testing machine manufacturer directly.

Every company wants to extend the production life of its drop test machines. For example, by using a conventional drop test machine with a hard chrome or nickel-plated metal surface; Or by using more chemical engineering coatings to prevent its surface wear or corrosion and promote its release. Since then, in pursuit of the same goal, people have started to use stainless steel and found practical solutions.

Here are some specific ways to help maintain the drop test machine to extend its life.

- You must lower the drop arm after each test. To avoid the deformation of the spring after the drop arm is reset for a long time, affecting the test effect. And each fall, please reposition the motor to stop rotating and then press the drop button.

- It is recommended that you add an appropriate amount of low-concentration oil to the pulley rod after the new factory installation of the biplane testing machine (it is strictly prohibited to add high-concentration anti-rust oil or oily corrosive substances).

- If there is too much dust in the oiled area, lower the machine to a lower part. And wipe off the oil before, and then re-oil.

- A drop testing machine is an impact mechanical device if your new machine has been used more than 500 times. Please be sure to tighten the screws to avoid failure.

- The lifting shaft and chain of the testing machine require you to apply lubrication regularly.

- The speed reducer is every six months to replace the transmission oil.

- If the machine is not working, you should cut off all power to ensure the cleanliness of the lifting shaft.

- Non-operators are not allowed to operate the drop tester.

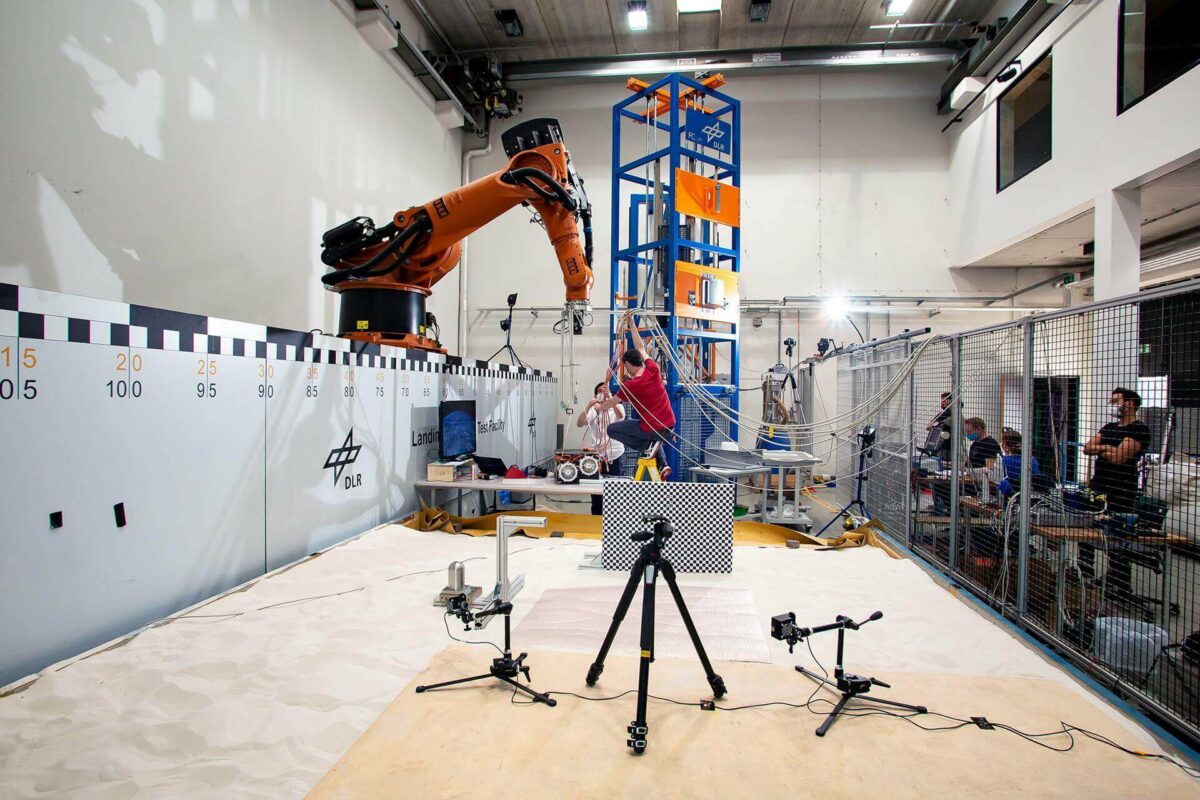

Drop test machines can work with other machines. Provide you with accurate data and classify your packaging according to international standards.

One option is to use a data logger for this operation. When the machine is placed on a truck, ship, or aircraft, it records movements (including drops) during transport that could pose a danger to the cargo. The data is recorded on a card, which you can then insert into the drop-test device.

In addition, the drop test machine will work alongside other machines to implement Amazon’s ISTA protocol. In fact, it will be crucial to work with e-commerce giants in the coming months. Below are some machines that can be used with drop testing machines.

- Clamping test machine to measure the ability to protect packages when exposed to horizontal pressure and vertical movement during automated storage.

- An inclined impact tester to simulate the horizontal impacts that can affect loads during transportation and loading/unloading.

- A compression tester to test the resistance of components to compression and creep.

- A vertical vibration machine simulates the vertical vibrations experienced by the load during transportation by road, rail, air, or sea, preventing their effects and protecting the goods being transported.

When operating the drop tester, there are some considerations you need to pay attention to:

- This equipment is testing equipment. Do not use this equipment for purposes other than the specified tests and materials.

- Please install the equipment in a suitable environment. Please place it in an environment with high indoor temperatures. Place in an environment with low humidity. (80% or less without condensation) A place where there is almost no dust.

- Please install the test material as required. Install the test material as required, otherwise unpredictable failures may occur.

- Be sure to turn off the power when performing wiring and maintenance operations. To prevent accidents and electric shock caused by loss of control of the machine during operation, be sure to turn off the power before working.

- Please note the following about the power supply of this equipment. The power distribution method is in principle three-phase 380V power supply. Please consult an electrical engineer or someone with equivalent knowledge of power supply and electrical engineering.

- Please be sure to use the power cord that comes with the equipment. If you find any abnormality in the power cord or power plug, please contact our company. Replace them with our service personnel or instruct them to do so.

- Do not use a fuse other than the specified fuse to prevent a fire or breakage of the internal circuit, etc. When replacing a fuse, use a fuse of the same type and shape as the original equipment.

- It should be noted that the application or the conditions being performed are highly hazardous and may result in injury or even death. To prevent accidental injury or death, be sure to observe carefully before moving and using the equipment.

Usually, drop test procedures are developed by test standards organizations such as ASTM, IEC, and ISTA. The drop test procedure can be carried out with the help of a machine. However, operator training can have a significant impact on results. In order to perform repeatable drop tests, you should consider the following factors:

Drop tester training needs to be consistent and documented. Since operators have a large impact on results, it is recommended that you ensure that training programs mitigate operator variability. This is guaranteed by a sound quality management system and test method validation procedures.

You should perform preventive maintenance on drop testing machines every year. Drop height should be determined using calibrated scales, preferably in accordance with approved reference standards.

A reliable drop test supplier will be of great help in this regard. If you have any questions about the operation of the drop testing machine, please contact the drop testing machine manufacturer first. They usually have a range of solutions for different conditions.

As a professional drop tester manufacturer from China. Linkotest has served many well-known enterprises and laboratories with our high-quality drop testers and great service. The drop testing machine has become an important tool to start a project, and it has been widely used in various fields such as medical, food, and pharmaceutical. Contact us today to find out all your drop test machine needs.